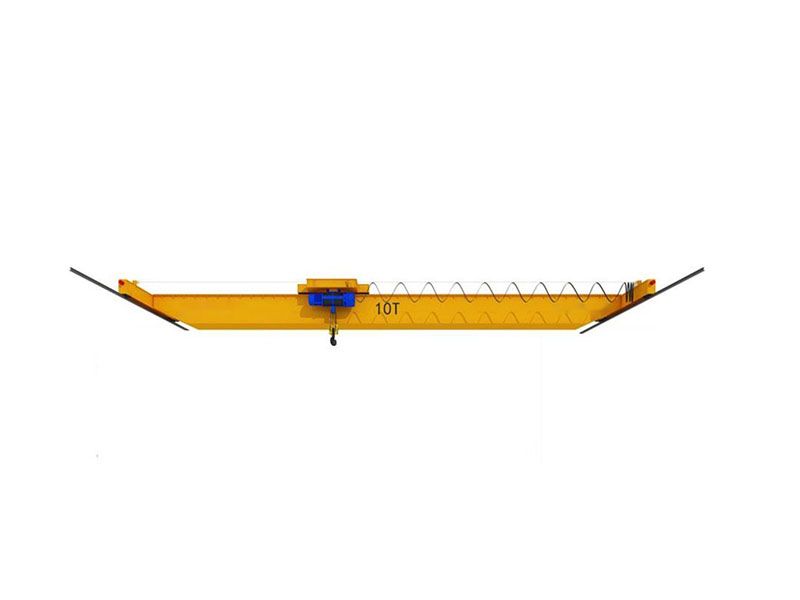

LDE type electric single beam crane

The LDE electric single beam crane is designed and manufactured according to JB/T306-1994, using an electric hoist as the lifting mechanism. The entire machine runs on two tracks. The single beam bridge crane has compact dimensions, low static height of the building, light self weight, and small wheel pressure. Widely used in industrial and mining enterprises, warehouses, mechanical processing workshops, metallurgical plant auxiliary workshops, material yards, power stations, etc. for transportation, assembly, maintenance, and loading and unloading operations, it can also replace ordinary double beam bridge cranes and be used in production workshops in the light textile industry and instrument industry. His work level is light and intermediate.The product is a type of crane developed in recent years based on the LDA electric single beam crane according to the needs of the market and users.Compared with the ordinary LDA electric single beam crane, this type of product has two independent operating electric hoists. These two electric hoists can independently complete the lifting work of the workpiece and cooperate with each other to complete the flipping of the large workpiece. At the same time, each operating handle can independently control the shared crane operating mechanism, and the price is only slightly increased compared to the ordinary LDA electric single beam crane. Therefore, it is an economical new type of lifting machinery.The commonly used lifting capacity is 1-25t, with a span of 7.5m-22.5m, using a three-phase 380V, 50Hz power supply, and working environment temperature of -25 ℃ -40 ℃. It can also be designed separately according to user requirements.