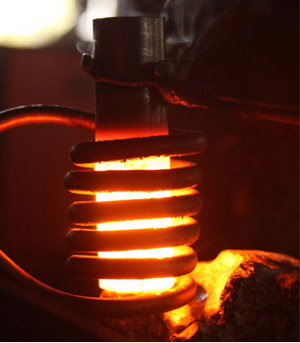

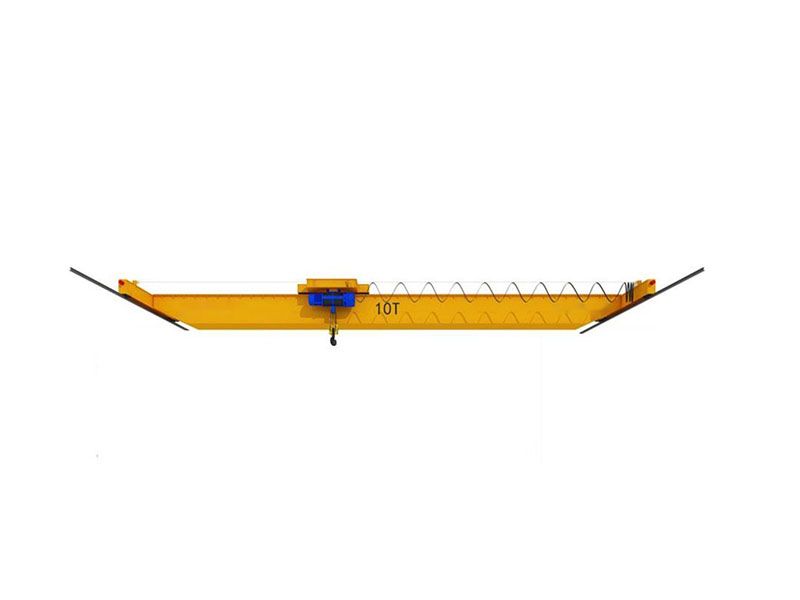

According to GB3836.1-2000 "Advanced Part of Explosion proof Electrical Equipment for Explosive Gas Environments: General Requirements" and GB3836.2-2000 "Explosion proof Electrical Equipment for Explosive Gas Environments - Part 2: Explosion proof Type" d ", the motor and electrical components of this crane are of explosion-proof type. When the explosion-proof level is ExdIICT4, the operating structure is subjected to mechanical fire protection treatment. The whole machine complies with the provisions of JB/T10219-2001 "Explosion proof Beam Crane", with explosion-proof levels of ExdIIBT4 and ExdIICT4, and has the characteristics of reasonable structure, beautiful appearance, and strong explosion-proof performance. The whole machine is used in conjunction with Hb and BCD explosion-proof electric hoists. Its maximum lifting capacity is 63t.

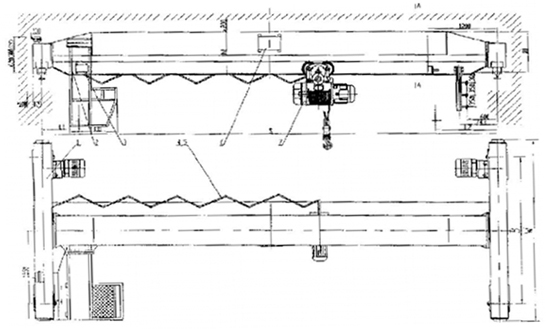

There are three types of explosion-proof beam cranes:

1. LXB explosion-proof electric single beam suspension crane.

2. LB explosion-proof electric single beam crane.

3. LHB explosion-proof electric hoist bridge crane. The work level is A3-A4, and the working environment temperature is -25 ℃~40 ℃.

This crane is suitable for explosive gas environments formed by combustible gases, vapors, and air in factories with explosion-proof levels not higher than B or C, and ignition temperatures not lower than T4 (135 ℃). The hazardous area used is Zone 1 or Zone 2, and it is not suitable for Zone 0.

Note: Zone 0: A place where explosive gas mixtures occur continuously, frequently, or for a long time under normal circumstances.

Zone 1: Places where explosive gas mixtures may occur under normal circumstances.

Zone 2: Places where explosive gas mixtures cannot occur under normal circumstances, and only occasionally occur for a short period of time in abnormal situations where equipment malfunctions or operational situations may occur.