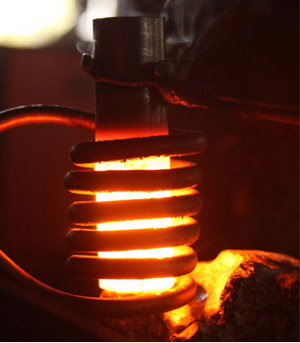

Chain electric hoist is a lightweight lifting equipment. The electric chain hoist consists of an electric motor, a transmission mechanism, and a sprocket. All chain electric hoists are produced according to international standards, with a beautiful appearance, sturdy and durable body. The internal gears are all high-temperature quenched, which increases the wear resistance and toughness of the gears. Advanced international technology is adopted, with fine workmanship and tight fit between gears. The lifting weight of chain electric hoists is generally 0.1-100 tons, and the lifting height is 3-120 meters.

The characteristics of the electric chain hoist include advanced performance and structure, small size, light weight, convenient operation, and a wide range of applications. It is very convenient for lifting heavy objects, loading and unloading work, maintenance equipment, and lifting goods. It can also be installed on suspended I-beams, curved tracks, rotating arm suspension rails, and fixed lifting points to lift heavy objects.

Structural characteristics of electric chain hoists: Product structure of electric hoists: The body is made of high-strength tensile shell or die cast aluminum shell, and precision manufacturing is carried out using thin-walled extrusion molding technology, with small volume, light weight, and high strength. The standard chain electric hoist has an independent gearbox system, which seals the secondary coaxial transmission gear mechanism inside the gearbox and adopts a long-life oil bath lubrication system. The powder metallurgy clutch of the electric hoist is used as an overload protection device, and the braking adopts a disc type DC electromagnetic field braking, which has a large braking torque, stability, speed, and low noise. The use range of electric chain hoists is very wide, mainly used in various industries such as factories, warehouses, wind power generation, logistics, docks, and construction. They are used for lifting or loading and unloading goods, and can also lift heavy objects for convenient work or repair of large machinery. The electric chain hoist is operated by the operator using buttons on the ground, and can also be operated from the control room or through wired (wireless) remote control. The electric chain hoist can be fixed and suspended for use, and can also be used with electric monorail cars and hand pushed/pulled monorail cars for walking.